Vibro Shifter

Use of Vibro Shifter

Varahi Engineers and Fabricators Shifter is for screening starch, pharmaceuticals, animal feeds, food product, agro product, agro chemicals, fertilizers, gum power, matel power, chemicals, Minerals. Agrochemicals, dyes, pigment, ceramics, minerals, paints, polymers, magnetic material papers etc.

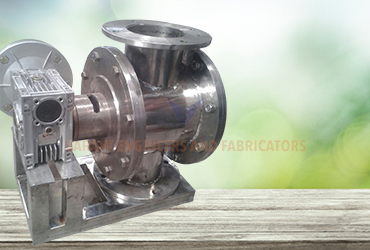

About Vibro Shifter

New technology shifter is giving horizontal, vertical and circular mechanical vibration. Vibro shifter is forcsreening dry power or wet medium. It is also useful for separation solid with: screen above its center of mass. Whole mass is suspended on coil springs, which gives thrust to screening unit by its own compression and de-compression. Spring allow unit to vibrates freely and also prevent transmission of vibration on floor. Number of screen decks and spacing frame assembled on circdar base frame. Screen is uniformly tensioned in all direction by center support. Specially designed vibrating motor generates vibration. Eccentric shaft is fixed on both side extended motor shaft. Eccentric weight is rotate with motor and generates vibration of whole masks.

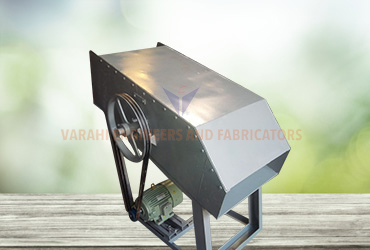

How Vibro Shifter Works

Material for screening is to be fed into upper screen deck. Fine material enter into lower deck after pass from top screen and coarser remain over screen. Material over each deck is automatically discharge from individual is charge spout. Over size material discharge rate can be increase by increasing horizontal throw. Horizontal throw is increases by rotation of upper eccentric mass. Maximum vertical vibration is desirable for clean the screen and dislodge material. Vertical and Horizontal plane vibration is change by lower weight. Angular position of upper and lower eccentric weight is for control circular motion of particles in the screen for getting better screening efficiency.

Automatically discharge from individual discharge spout. Over size material discharge rate can be increase by increasing horizontal throw. Horizontal throw is increase by rotation of upper eccentric mass. Maximum vertical vibration is desirable for clean the screen and discharge material. Vertical and tangential plane vibration is change by lower weight, Angular position of upper and lower eccentric weight is for contro circular motion of particles in the screen for getting better screening efficiency.

| Model | Motor (HP) | Screen Area (M2) | Screen Dia (MM) |

|---|---|---|---|

| WS-600 | 0.5 | 0.5 | 600 |

| WS-750 | 0.5 | 0.45 | 750 |

| WS-900 | 1 | 0.6 | 900 |

| WS-1200 | 2 | 1.13 | 1200 |

| WS-1500 | 3 | 1.75 | 1500 |

| WS-1800 | 5 | 1.85 | 1800 |

Other size unit can be offer based on request.

Production is totally depend on material and size of screen. All the data given are nominal only. It may vary widely from case to case depending upon many factors.