Air Classifier

Use of Air Classifier

Varahi Engineers and Fabricators Classifier is to Classify dry powder like Cement, Flour, Chemicals, Pigments, food colors, Minerals, Sand, Cement, etc.

About Air Classifier

Centrifugal type closed circuit Air Classifier is to separate coarse and fine dry powder material from 60-350 meshes. This machine is not grinding material but for getting uniform size of powder at out-let. It can either remove coarser particles like free iron, their oxides, grit, silica, heavy impurities, or fine/light foreign material as to de-dust a product. Deflector blades produce centrifugal force and air current to separate particles and impurities on weight basis. Material fed into inner tube from inlet hopper. Rotating distributor plate distributes powder radially outward into upward sweep of circulating air stream generated by deflector blades. Every particle is got downward gravity force and upward air stream force. Gravitational force is higher on grits and impurities due to higher weight. Upward air stream force is not enough against gravity force. Particles prevails gravity force than flows downward force and pass it through tail cone. Lightweight (fine) particles move upward because air stream force is more than gravity force on it. Both raw of Whizzer blades are provide to adjust resistance to particles by add/remove blades. It helps to reduce or increase the escape of particles towards deflector blades. Whatever Particles pass through both whizzers will discharged into circular space between inner and outer drum due to centrifugal force and discharged through center fine cone. Air after releasing fine in outer cone returns through the deflectors vanes to the inner cone, setting up a continuous air circuit. Thus heavy particle discharge through tail cone and fine are through fine cone. Fine and coarse grade separation ratio is varying from 95-5 to 60-40. Pattern of classification can be change by regulation and controlling air stream. Air stream can be reduce by closing air dampers and increase by opening. Dual purpose is removing heavier impurities for better quality and removes grit of particle for better size distribution.

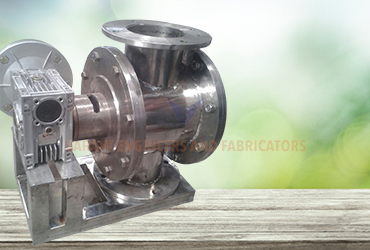

Classifier Design

Self-contained unit is consists one or two disc with whizzer blades rotate inside cone. Top chamber is consists rotating deflector blades. Material feeding tube is mounted co-axially inside hollow shaft. Fed material distributor is fitted bellow lower whizzer hub. Heavy-duty bearing is fitted in housing for support vertical hollow shaft. Hollow shaft, whizzer blades, distributor plates, and deflector blades are rotated by motor to produce the internal air circuit. Upper/lower whizzer cones, outer/inner drum, damper, deflector vanes, fine/tail cone, bearing housing and hopper are fitted in body.

All the data given are nominal only. It may vary widely from case to case depending upon many factors.

Screw Conveyor

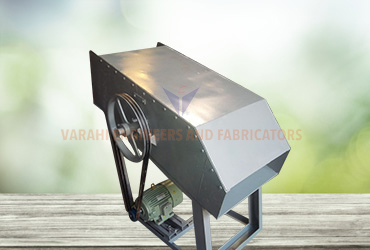

Varahi Engineers and Fabricators Screw Conveyor / Feeder range and specification.

Varahi Engineers and Fabricators screw conveyor or material feeder are available in many different dia and length. We have supply screw min. Dia. 100 mm to 600 mm, in min. length as per requirement. Motor HP and out put is totally depends on fed material. It can be design as per output requirement. Out put can be adjust as per requirement.

All the data given are nominal only. It may vary widely from case to case depending upon many factors.

Use of screw conveyor / Feeder

Varahi Engineers and Fabricators Screw conveyor is for is for reduce manpower (atomization), increase efficient, increase productivity, reduce wastages and nullify dusting. It consume low power consumption It convey or feed various dry solid material for any dry powder, small ice cube, seeds, minerals, sand, cement, ceramics, fertilizers, spices, plastic granules/powder etc.

Different example of screw use: To discharge bin to load into blender or soil at height. Connect outlet of one machine to inlet of other machine.

Screw feeder are small size. It is used for feed material in any machine. Main purpose of feeder is uniform material feeding for increase product quality and productivity.

About Screw Conveyor / Feeder

Material is fed on end and it is conveyed by spiral flight towards other end. It is for convey material horizontal, vertical and incline in bulk from one place to other. Outer shell is made from round Pipe OR U-trough. Screw flights welded on heavy-duty pipe. Shaft is connected to screw pipe, rotates in bearings. Both side bearings are mounting in bearing housing. Stuffing box are provided both end to prevent leakages. Screw is rotate through suitable size gearbox, motor and sprockets. To support longer screw, hanger bearing is placed wherever require. Different screw flight like spiral, paddle, cut & folded, ribbon, etc.

Optional Features

SS material, Outer jacketed for cooling or heating, Bottom bush. Bush (bearing) for pharmaceutical, and mounting as per customer layout.