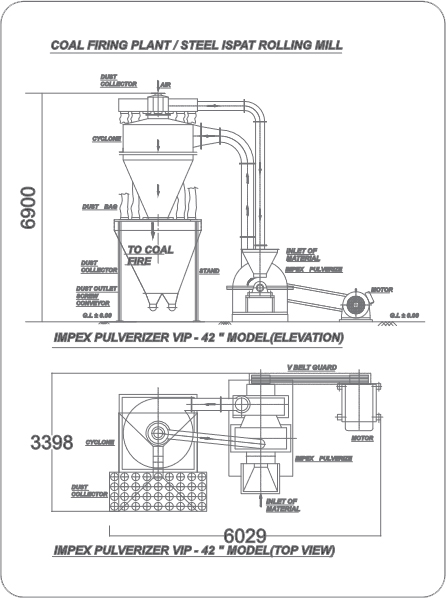

Coal Firing Plant

Important Technical Information: Pulverization in IMPACT PULVERIZER is achieved by the impact of rotating hammers and grinding plates. Row material from the feed hopper enters the rotary feeder and spills into the grinding chamber. Continuous and strong beating reduces the lumps into small particles and the air stream blowing through the pulverizer carries the ground material towards outlet. The oversize particles are rejected by the whizzer classifier and returned to the grinding chamber. They are beaten further and reduced to cyclone collector dust collector provides clear air to the mill and also complete pulverizing operation free from dust.

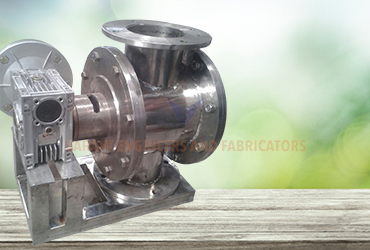

Body: Main body (grinding chamber) made out of CI with replaceable grinding plates of different designs suit able for different products. A metal trap is provides to remove heavy foreign material.

Feeder: Automatic feeding arrangement with variable speed rotary valve is provided for controlled feed. Rotor: Made of thick plate mounted on main shaft with hinged hammers to prevent breaking hammers. This shaft is support on two dust tight housings fitted with heavy doth bearings.

Whizzer: Conical whizzer provided with adjustable whizzer blades to control less in the range of 100- 300 mesh, depending upon the material.

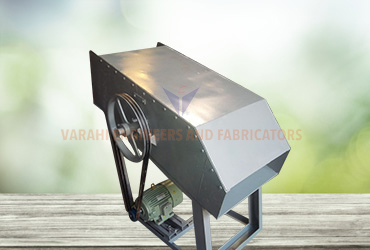

Blower: Heavy duty type with changeable blades.

Cylone: Made for better separation efficiency. Dust collector provided with bag house to retain fine particles.

Production Capacity: fineness and HP of motor and nominal only - Provided with bag

house two and vary from case to case depending upon several factors.